2. Internal dynamics in concrete and model systems of concrete: 3D particle tracking, flow and concentration profiles.

Principal investigator(s) – PI

- Dr. Günter K Auernhammer

Leibniz-Institut für Polymerfoschung Dresden e.V.

Researcher(s) in charge – RI

- M.Sc. Himanshu P. Patel

Leibniz-Institut fuer Polymerfoschung Dresden e.V.

Subject Area

Granular Matter, Particle Tracking, Rheology, Non-Newtonian fluid

Term

2018-2021

Project Identifier

Deutsche Forschungsgemeinschaft (DFG) – Projekt number 387100398

Project Description

The flow of concrete is of enormous importance in the modern building technology. Despite intense studies over the last decades, still many fundamental questions concerning understanding of the flow process are still under debate. Cementitious materials (cement pastes, mortars and concrete) are suspensions of particles with a size distribution that spans several orders of magnitude (ranging from nano-metric additives over micro-metric cement particles to milli-metric sand and gravel particles). These particles have very specific influences on the flow properties, even in simple situations, like the flow of a model mortar containing only cement and sand particles during the dormant period of the hydration reaction. The aggregation of the cement particles generates a yield stress that has to be overcome to allow flow. When the concrete is flowing the concentration of larger particles is reduced close to walls, due to flow-induced particle migration. The combination of both processes leads to the formation of a plug-like shear profile, with a thin strongly sheared lubrication layer close to the walls. Spatially highly resolved optical studies of this process are naturally hindered by the opacity of cementitious materials. The aim of the proposed project is to elucidate the interplay between the processes behind the formation of a lubrication layer. To do so, a highly transparent model system shall be developed and carefully cross-checked to exhibit all relevant properties of real cementitious material (particle interactions and concentrations, density difference, macroscopic flow properties and flow profiles). Such a model system will then allow the investigation with high spatial and temporal resolution. We will apply non-destructive and fast 3D imaging techniques and use single particle tracking at two length scales. The flow of the sheared model cement paste (particle diameter typically between 10 µm and 50 µm) will be investigated by high-speed confocal microscopy. This will result in series of 3D images from which the trajectories of almost all particles can be extracted. The knowledge of the particle trajectories allows to elucidate the relation between particle interaction, flow profile and size and structure of the aggregates. The analysis of the motion of sand particles follows similar lines, however, using different imaging techniques. Within the SPP we will validate our experimental approach through comparisons to other experimental and theoretical groups in the program. Our experimental approach will be enhanced through the exchange of results between the different groups and combination of experimental methods on the same sample. We intend to provide insight in the interplay between the different processes behind the formation of a lubrication layer.

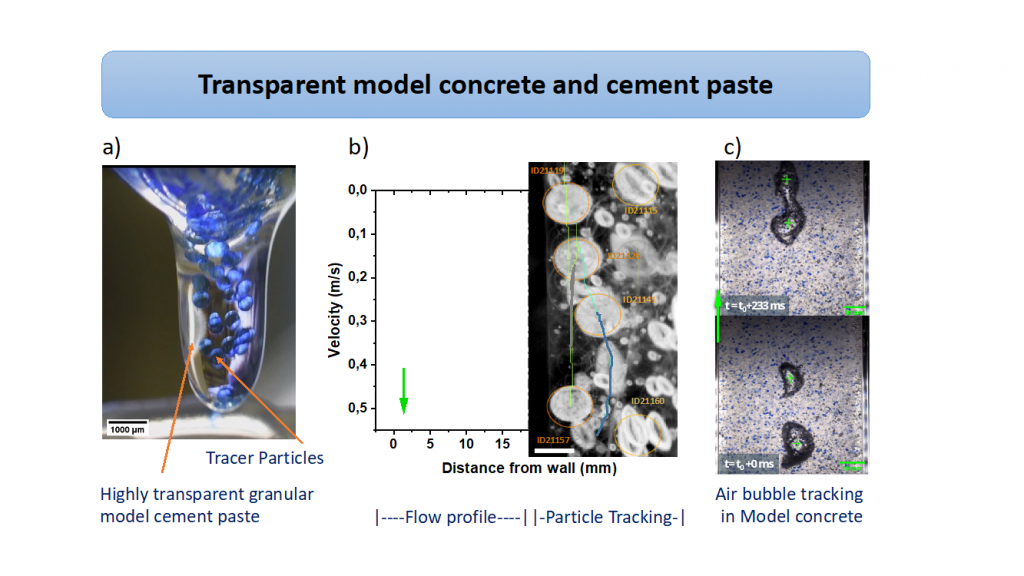

a) Image of the granular model cement paste showing very little light scattering. Free outpouring of the granular model cement paste (particle volume fraction ~ 47 vol% with additional tracer particles).

Scale bar 1 mm

b) Example of tracer particle observation in pipe flow using the transparent model concrete, Flow profile averaged from tracks of tracer particles (compare image), also Materials & Design (2020): 108673. Scale 1 mm

c) Rising air bubbles in model concrete (in cooperation with Prof. Haist). Scale bar 10 mm

Publications

Materials & Design 193

Presentations

Simulation-based modelling of time- and shear-dependent disperse and rheological properties of cement suspensions

Rheologentagung 2019 | Berlin, Germany