10. Flow-induced particle migration in cement-based materials at high shear rates

Principal investigator(s) – PI

- Prof. Dr.-Ing. Viktor Mechtcherine

Technische Universität Dresden, Institut für Baustoffe

Researcher(s) in-charge – RI

- M.Sc. Shirin Fataei

Technische Universität Dresden, Institut für Baustoffe

Subject Area

Construction Material Sciences, Concrete Rheology, Pumping, Numerical Simulation of Fresh Conctete

Term

2017-2020

Project identifier

Deutsche Forschungsgemeinschaft (DFG) – Projekt number 387095311

Project Description

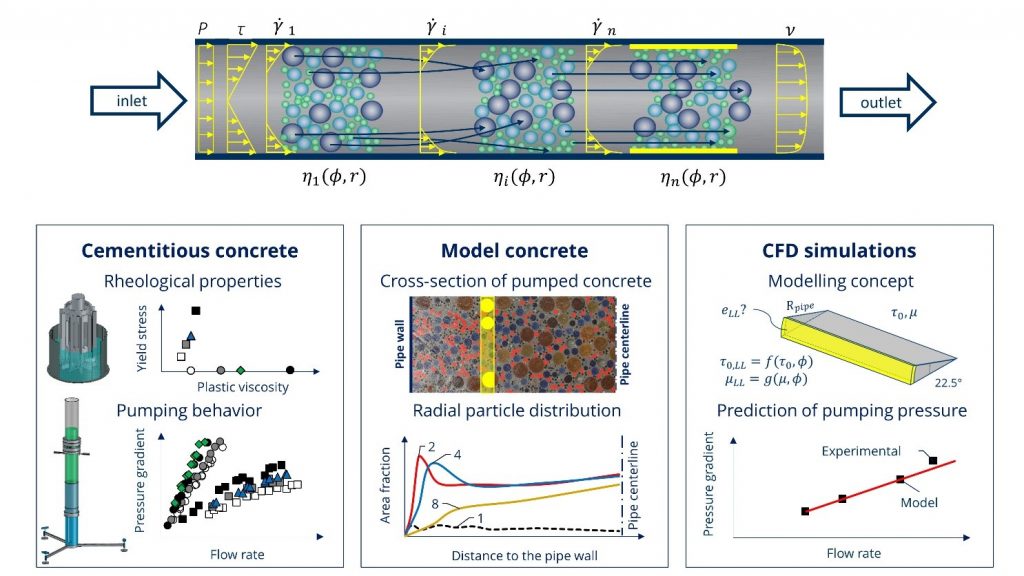

The flow of heterogeneous, cementitious suspensions at high shear rates induced by pumping is a complex process greatly influenced by the material composition and its ability to generate a lubricating layer (LL), which reduces the friction at the pipe wall-to-concrete interface. Pumping behavior depends both on the rheological properties and the thickness of such lubrication layer and on the rheological properties of the concrete bulk. The formation of the lubricating layer is mostly related to flow-induced particle migration (FIPM) under high shear rates. To date, there are no in-depth insights on FIPM in concrete under high shear rates and its effect on lubricating layer formation; existing investigation approaches are insufficient. The project at hand is to enable the attaining of a clear understanding of causality and underlying mechanisms of FIPM in concrete and eventually to apply this knowledge to realistic description and prediction of the pumping process. The consequences of FIPM on the formation of LL and on the resulting material flow behavior, with the focus on pumpability, are to be established as the basis for a purposeful analysis of the concrete pumping process and its implementation in numerical simulation. These main objectives will be accomplished stepwise by first developing adequate approaches for experimental coverage, fundamental analysis, and description of particle migration in concrete at high shear rates followed by experimental investigation of the effects of rheological properties of the suspending medium, i.e., a paste of cement and fines, on FIPM. Next, the effects of particle size shape, size distribution and packing density on FIPM will be investigated and the analysis of cause-effect relationships between particle migration, the formation of LL, flow pattern and pressure-flow rate function will be performed. The obtained data and insights will be then used for developing a numerical representation of FIPM for CFD analysis, which will be applied in predicting the pumping behavior of concrete in the pipeline. For validation, the results of full-scale pumping experiments performed in an earlier research project will be used. Accordingly, the work program is comprised of a comprehensive combination of appropriate experimental methods, novel measuring techniques and new approaches to mimic particle migration adequately, enriched by a strong link to numerical simulation. It consists of three segments: 1) experimental investigations focusing on the qualitative and quantitative analysis of FIPM, formation of LL, and the rheological properties of LL and concrete bulk; 2) numerical simulation based on implementation of the FIPM into existing CFD-model to calculate the thickness and rheological properties of LL and, consequently, of pumping behavior; 3) consideration of the pumping process, in which the prediction of concrete flow can be compared with the available results of full-scale pumping experiments.

Publications

Cement and Concrete Composites 107 (2019)

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 303–310 (2019)

Materials and Structures 53 (2020)

Materials & Design 193 (2020)

Cement and Concrete Research 132 (2020)

Materials 13 (5) (2020)

Cement and Concrete Research 147 (2021)

Frontiers in Materials 144 (2022)