4. Simulation based modelling of time- and shear-dependent disperse and rheological properties of cement suspensions

Principal investigator(s) – PI

- Dr.-Ing. Hans-W. Krauss

Technische Universität Braunschweig, Institut für Baustoffe, Massivbau und Brandschutz (iBMB), Fachgebiet Baustoffe - Prof. Dr.-Ing. Arno Kwade

Technische Universität Braunschweig, Institut für Partikeltechnik (iPAT) - Prof. Dr.-Ing. Dirk Lowke

Technische Universität Braunschweig, Institut für Baustoffe, Massivbau und Brandschutz (iBMB), Fachgebiet Baustoffe - Prof. Dr.-Ing. Carsten Schilde

Technische Universität Braunschweig, Institut für Partikeltechnik (iPAT)

Researcher(s) in charge – RI

- M.Sc. Dimitri Ivanov

Technische Universität Braunschweig, Institut für Partikeltechnik (iPAT) - M.Sc. Mahmoud Eslami Pirharati

Technische Universität Braunschweig, Institut für Baustoffe, Massivbau und Brandschutz (iBMB), Fachgebiet Baustoffe

Subject Area

Construction Material Sciences, Rheology of Cementitious Materials, CFD-DEM Simulations

Term

2017-2020

Project Identifier

Deutsche Forschungsgemeinschaft (DFG) – Projekt number 387066140

Project Description

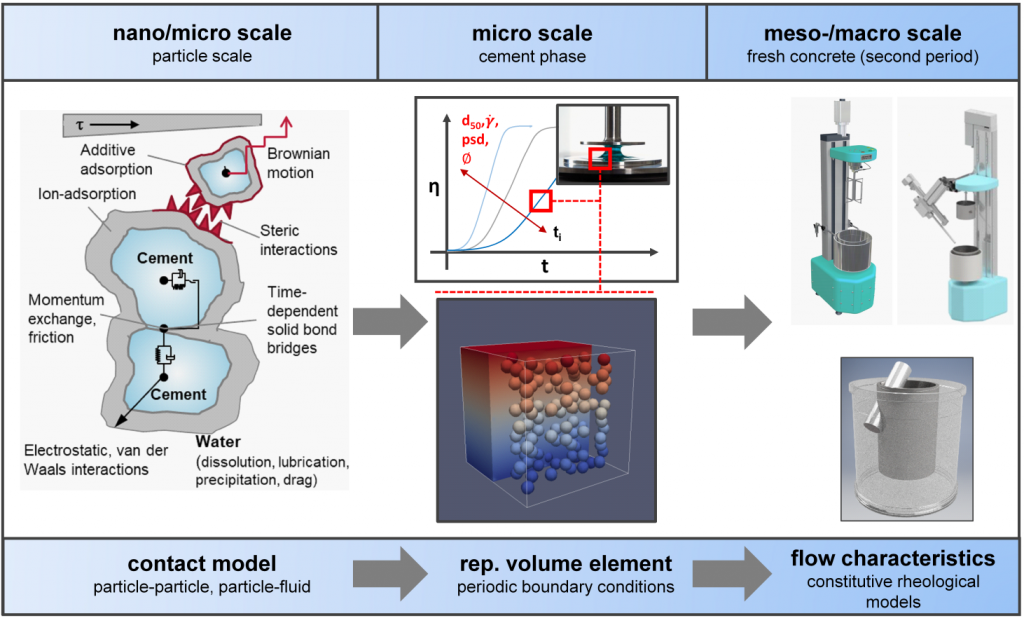

The aim of the project is to develop enhanced constitutive models for the prediction of rheological properties of cementitious materials based on chemical and physical particle and fluid characteristics. Bridging the gap between fundamental insights into chemical and physical processes at nano as well as micro scale and the macroscopic flow behavior, the project contributes for overcoming limitations of existing constitutive rheological models. Thereby, a more reliable simulation and modelling of concrete flow even for complex processing steps with time-variant shear history, such as pumping, 3D printing or spraying, is enabled. To that end, the time- and shear-dependent disperse and rheological properties of cementitious suspensions are investigated and modelled based on fundamental material properties and interactions with the help of coupled CFD-DEM simulations. With the help of the simulations, the basic interactions depending on numerous chemical and physical particles and fluid characteristics, mixture composition and processing parameters will be modelled comprehensively. New time-dependent contact models are developed and used for the coupled CFD-DEM simulations. The results of the simulation environment are calibrated and validated by different experiments. The properties of particles and fluid relevant for the simulations are investigated in cooperation with other working groups using different reacting and non-reacting technical and model particulate systems. The disperse and rheological properties of the suspensions are characterized comprehensively. Relevant particle and fluid characteristics are investigated by rotational rheometer tests. The microstructure effect on the rheological properties is described. Therefore, the agglomeration state and the rheological properties are characterized for different shear rates, time steps and shear histories with and without regard for hydration effects. Moreover, the particle size distribution and the agglomeration state of the pastes are determined under shear conditions by a laser backscattering method integrated into a new coaxial cylinders rheometer setup. Based on the simulation and experimental results the time- and shear-dependent microstructure effects are implemented into existing constitutive models enabling the consideration of thixotropic effects and ageing effects due to cement hydration. Being a key parameter for constitutive models and multi-scale modelling, a special focus will be on the determination of local shear rates acting on the paste phase. The approach will enable capturing realistic shear parameters for the simulations and experiments at micro scale, hence allowing a more reliable scale-up and modelling.

Publications

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 588–595 (2019)

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 602–609 (2019)

Materials and Structures 53 (2020)

Materials 13 (9) (2020)

Frontiers in Materials 144 (2022)