16. Rheology of the lubrication layer based on a two-phase liquid-granular flow approach

Principal investigator(s) – PI

- Prof. Dr.-Ing. Rüdiger Schwarze

Technische Universität Bergakademie Freiberg, Institut für Mechanik und Fluiddynamik

Researcher(s) in-charge – RI

- Dr.-Ing. Martin A. Haustein

Technische Universität Bergakademie Freiberg, Institut für Mechanik und Fluiddynamik

Subject Areas

Fluid Dynamics, Concrete Rheology, Numerical Simulation

Term

2018-2021

Project identifier

Deutsche Forschungsgemeinschaft (DFG) – Projekt number 387065607

Project Description

Concrete is a highly efficient building material used from mankind for thousands of years. It‘s composition is optimized continuously to match the desires of modern building concepts like high rise buildings, bridges and tunnels.

The material is a mixture of cement, sand, water and coarse aggregates, as well as chemical additives, that modify the rheology of the concrete. The description of the flow behavior of the complex material is highly dependent on the exact composition. Especially the nearly continuous particle size distribution from a few microns to some centimeters are of high interest for the workability and durability.

For the pumping of concrete though pipes, the description of the rheology is a demanding task. It is known that during the transport a segregation of the particles can take place, which leads to a thin layer depleted of coarse material at the pipe wall. This so called lubrication layer is of high importance, as it allows the transport over long distances without an extremely high pressure loss, that would hinder the pumping.

On the other hand, this segregation leads to inhomogenities that may be unwanted at the construction site. A homogeneous concrete is preferable. Here, the understanding of the demixing process during the transport is highly important for the optimization of the material for upcoming tasks like the additive manufacturing.

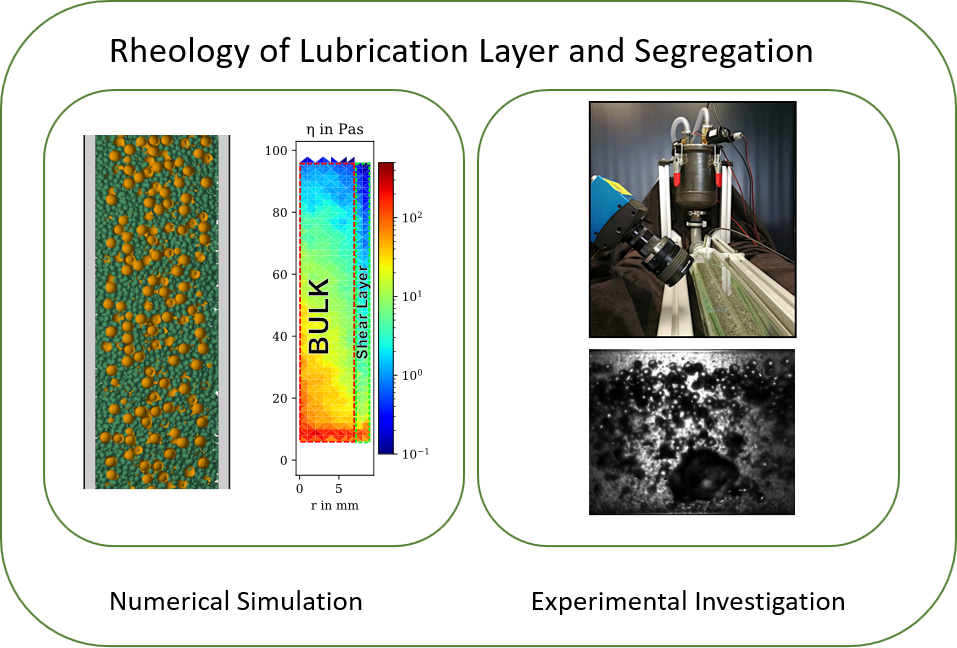

In the context of the sub-project „Rheology of the lubrication layer based on a two phase liquid-granular flow approach“, a model experiment is to be developed next to numerical simulations. This should help to understand the mesoscopic processes leading to the formation of a lubrication layer, especially under the consideration of the pumping procedure. It is assumed, that the pumping with a double-piston pump and the resulting pulsating flow has a significant influence on the segregation. For this purpose, optical methods like particle image velocimetry (PIV) and particle tracking velocity (PTV) are used as well as numerical methods like the discrete element method (DEM) and the finite volume method (FVM).

Publications

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 596–601 (2019)

Materials & Design 193 (2020)

Materials 13 (5) (2020)

Frontiers in Materials 144 (2022)